Mercury contamination in oil and gas systems which have reached their end of life.

Even if your system has produced fluid containing low concentrations of mercury over its operational life, it is highly likely product facing infrastructure is still heavily contaminated. Mercury will deposit in scales resulting in the potential for both a major environmental release or worker exposure incident come decommissioning if teams are not appropriately informed.

On-site Sampling

We core samples of decommissioned product facing pipework and vessels on site, which can be used to map mercury contamination across the whole process or pipeline.

On-site Analysis

We perform semi-quantitative analysis in-situ and quantitative analysis of cored samples in an on-site lab, meaning we can react to results in real-time.

Decontamination

We can provide support during a decontamination campaign monitoring the efficacy of mercury removal.

Decommissioning Services

Decommissioning is the process by which something is shutdown and/or removed from service. Within the upstream oil and gas industry, this involves plugging and abandoning oil and gas wells and removing or repurposing topside and subsea infrastructure. Decommissioning, as mandated in a range of national policies, should happen in a safe and environmentally and socially responsible manner.

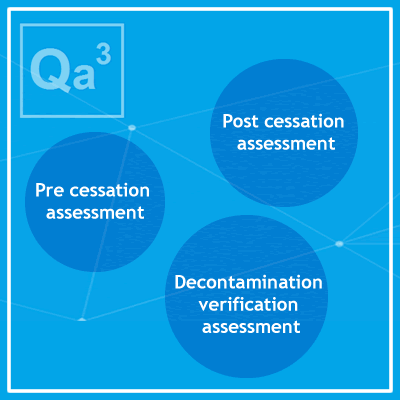

Our typical, recommended approach follows the below two or three stage programme:

Pre cessation assessment

(asset still in service)

A study investigating mercury content of your fluids whilst still in production will allow us to identify where in your system will likely be contaminated at end of life. This will assist in planning the most appropriate remedial actions. Samples will be taken and analysed on site (see our mercury page for more details).

Post cessation assessment

(asset no longer producing)

A study investigating the contamination in various systems. This will involve surface mercury determinations, scale characterisation and mercury in whole steel analysis. If significant contamination is observed, a decontamination programme will need to be undertaken. In this scenario, we can also provide stage 3 - post decontamination.

Decontamination verification assessment

A study investigating the efficacy of the utilised decontamination to confirm compliance with any prevailing regulations (depending on global location).

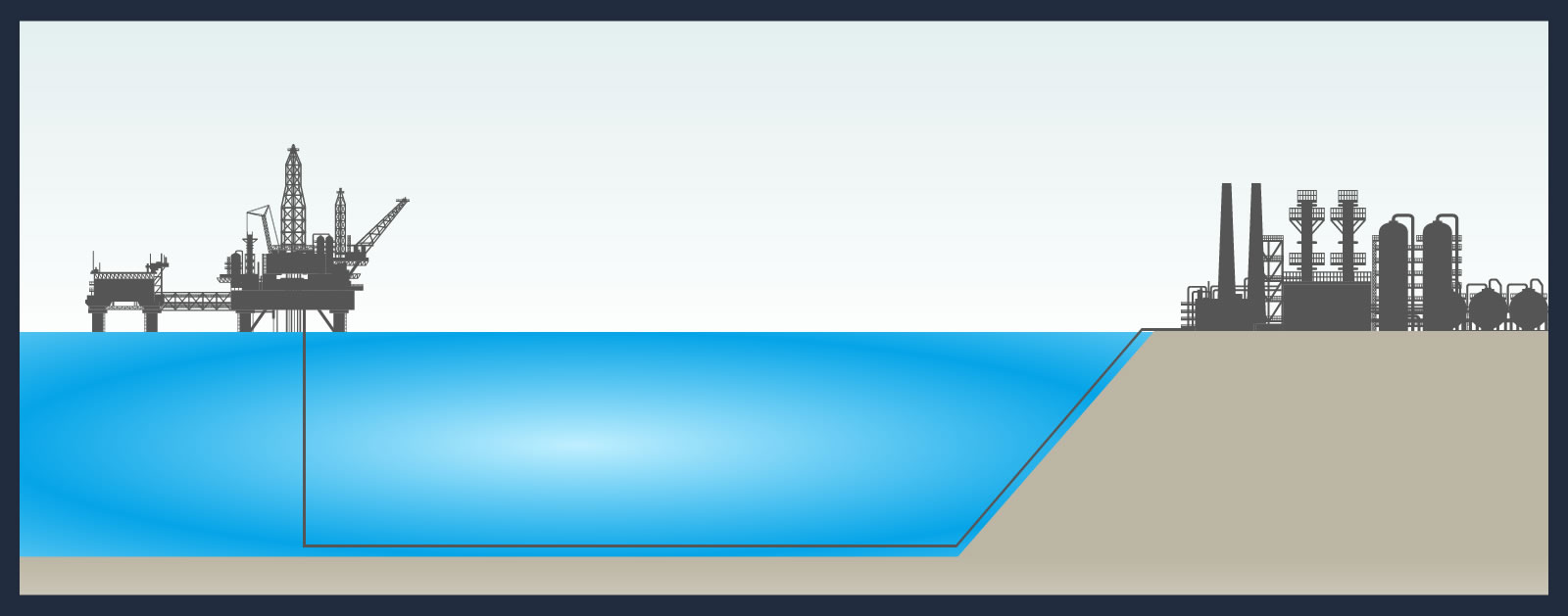

Click the blue tabs below this image to see what Qa³ can provide across your system.

Offshore installationskeyboard_arrow_up

Top side is typically removed and recycled onshore. Consideration should be given to the presence of trace contaminants in steel and scale, as without decontamination these would be released to atmosphere during smelting.

Qa³ can quantify mercury and various other contaminants in topside infrastructure.

Subsea infrastructurekeyboard_arrow_up

Pipelines could potentially be left in situ after an assessment of the trace contaminants present and, if required, a decontamination treatment.

Leaving pipelines in situ would remove the environmental impact of lifting operations and will benefit marine ecosystems, for example providing framework to support reef formation.

Qa³ have experience of pipeline decommissioning projects with the primary aim of minimising emission of mercury to local aquatic ecosystems.

Onshore facilitieskeyboard_arrow_up

Decommissioning onshore facilities clearly won’t pose a threat to aquatic systems, however the fate of scale bound contaminants in the product facing infrastructure needs to be considered, as without decontamination these would be released during smelting.

Qa³ can provide various services investigating trace contaminants across onshore systems destined to be decommissioned.

Summary of decommissioning services:

- Assessment of mercury contamination

- Scale characterisation and compositional analysis (arsenic / NORM / heavy metals)

- Evaluation of the efficacy of decontamination solutions

- Steel compositional analysis – primarily investigating heavy metal content

- Consultation services with respect to trace contaminants at asset end of life

Want to know more about our decommissioning services?

One of Qa³'s core aims is to assist oil and gas companies with their understanding of mercury within their processes

Companies we work with...